Air-flowing type Dryer machine ,also known as hot air pipeline drying machine ,using the principle of airflow drying instantly ,loading the wet wood shavings and sawdust into the drying tube by the screw conveyor.Under the transport and dispersion of the high speed hot air, the moisture in the wet material is evaporated,then we can get the dry final prod...

Air-flowing type Dryer machine ,also known as hot air pipeline drying machine ,using the principle of airflow drying instantly ,loading the wet wood shavings and sawdust into the drying tube by the screw conveyor.Under the transport and dispersion of the high speed hot air, the moisture in the wet material is evaporated,then we can get the dry final product for further processing.

Introduction of airflow dryer:

♦ Raw materials should be sawdust, mineral granule, coal powder, grain, and the moisture 20-50% of raw material can be final moisture 8-12% .

♦ Diameter of raw materials: 3-5mm.

♦ Temperature of Hot Air in the dryer: 180-250 °.

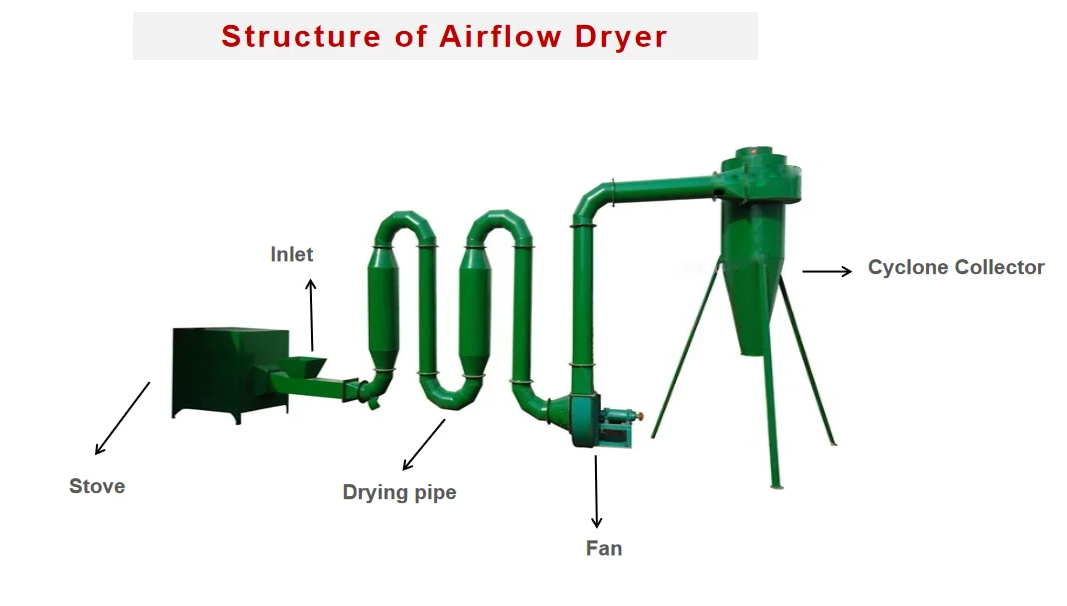

♦ Working principle: The stoves (boilers) generate hot air,which is blowed by the fan to pass the whole pipes and dry the materials in the process.

♦ This dryer reduces the moisture to 8-12 % with the advantages of lower cost consumption and high efficiency.

♦ The dryer for charcoal briquette machine is equipped one fuel boiler, inlet, steel pipe, exhaust blower (fan), cyclone. Wet materials are input into the hopper. The fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhaust blower (fan) quickly. And then hot air is flowing and going though the curving pipes and buffer (drying chamber) of dryer, thus wet materials is finished to dry, and the dried materials are expelled out by the exhaust blower (fan).

Structure characteristics:

1 It is using the rotary feeding type. The material can be dried uniformly by using small motor.

2 The heating method is by indirect way, which can prevent high temperature to fire the material.

3 The end of the dryer adapts special device, which can make sure only the material which have met the requirements can be pumped out by the air fan.

The discharging place has the dust removing device, which can separate the material and water. Also it can reduce the dust during working.

Installation:

1 After the machine is installed, turn on the air fan, checking the rotating direction of the air fan and make sure the suction strength of the discharging place is normal.

2 Tie the opening cloth bag in the discharging place.

3 Adding fuel in the hot air furnace, then burn the fuel. Then open the air fan. When the temperature goes to 160℃, please transfer the material to the dryer and then begin to dry.

Attentions:

1 Motor should be good grounding.

2 The exhausting pipe of the machine should not be indoor. It should be added with a pipe to the outside. The pipe should be 500mm higher than the room.

3 No big material added to the inlet ..

4 If the inlet feeding is not that continuously, you can check the air fan vane and clear the material on it.

| Model | Power(kw) | Capacity(kg/h) | Dehumidity Rate | Weight(kg) | Dimension(M) |

| 219 | 4 | 400-500 | 35% | 1000 | 8*1.5*3.5 |

| 325A | 5.5 | 600-800 | 40% | 1500 | 10*1.5*3.5 |

| 400 | 7.5 | 1000-1200 | 50% | 2500 | 14*1.5*4.8 |

Save Time! Get A Detailed Quotation Quickly.