Dry distillation carbonization furnace is special used for log, wood, jute stick and other long rod-type biomass characteristics, adopts horizontal structure, cart entry and exit raw material and the advanced hot gas dry carbonization process technology, using a unique carbonization flue gas (volatile hydrogen material and tar, etc.) Back Burning Technology...

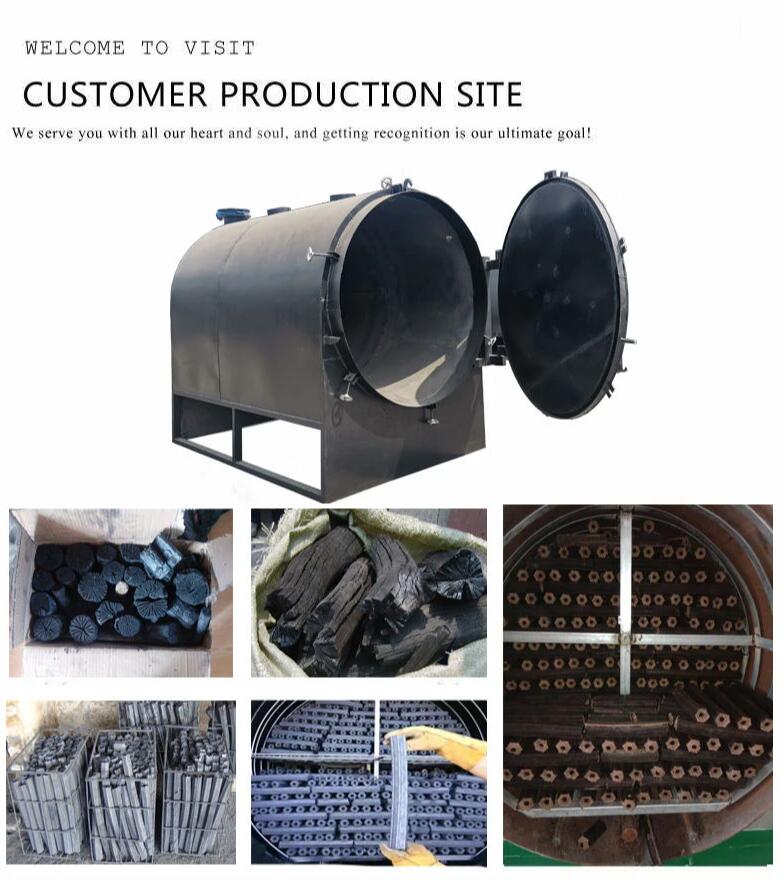

Dry distillation carbonization furnace is special used for log, wood, jute stick and other long rod-type biomass characteristics, adopts horizontal structure, cart entry and exit raw material and the advanced hot gas dry carbonization process technology, using a unique carbonization flue gas (volatile hydrogen material and tar, etc.) Back Burning Technology, make full use of the flue gas produced by carbonization process, meet the thermal needs of carbonization furnace itself, greatly increase the carbonization rate, and easy to operate, safety and environmental protection, high production efficiency, can save a lot of energy, is the ideal equipment for carbonizing the long rod type biomass material.

horizontal biomass dry distillation carbonization furnace consists of inner tank, insulation, furnace door, rail car , combustible gas reburning pipe, dehumidifying buffer tank, burner, exhaust pipe, and thermometer. The gasifier and flue gas purification device are the optional machine. This furnace using anaerobic dry distillation principle to remove volatile substances in biomass material, to carbonize the biomass material, carbonization process: Feeding raw material and sealing the furnace→Preheating and drying the raw material → Anaerobic carbonization →Cooling and discharging the carbon, total four steps.

Operation steps of Carbonizaton Furnace:

1. Preparing the material; if it's the wood, please make sure the size is not with big different;

2. Open the furnace door, and put the mateiral inside directly; or you can put the mateiral on the rail car to send the material into the inner pot.

3. Seal the furnace, and check the valves and other things, make sure the furnace is ok before firing.

4. FIre the furnace and to make the charcoal. This step, there is the combustible gas to produce and this gas can be sent to the bottom of the fire mouth to let the machine heat.

5. After the charcoal finished and cooled, then use the rail car to delivery the charcoal out. Then all the steps are finished.

Product Paramenters:

| Specifications of different model Wood Coal Sawdust Carbonization Furnace | |||||

| Model | Inner size(m) | Dimension(m) | Weight(kg) | Carbonization cycle | Output |

| 0815 | 0.8*1.5 | 1.8*1.1*1.3 | 400 | 8-10h | 150-200kg |

| 1215 | 1.2*1.5 | 1.9*1.5*1.8 | 650 | 10-12h | 200-300kg |

| 1515 | 1.5*1.5 | 1.9*1.8*2.3 | 1000 | 18-20h | 400-500kg |

| 1220 | 1.2 * 2 | 2.3*1.6*1.8 | 1200 | 18-24h | 500-600kg |

| 1330 | 1.3*3 | 3.3*1.8*2.3 | 2300 | 18-24h | 700-800KG |

| 1530 | 1.5*3 | 3.3*2*2.4 | 2800 | 18-24h | 800-1000Kg |

| 1545 | 1.5*4.5 | 4.7*1.9*2.3 | 3200 | 18-24h | 1800-2000kg |

| 2060 | 1.9 * 6 | 6.2*2.3*2.8 | 7000 | 18-24h | 2800-3000 kg |

| Carbonization Time | 4-6 hours | ||||

Charcoal briquette making line:

How to make charcoal from sawdust?

1. Wood crusher: A crusher will help you to reduce the size of your raw material to less than 5 mm.

2. Dryer: For small capacity drying, you can choose the air flow dryer with small investment. If your capacity is bigger, a rotary dryer will be a better choice.

3. Wood briquette machine: Press raw material into wood briquettes.

4. Charcoal furnace: After carbonization, wood sawdust briquettes become smokeless charcoal.

5. Other accessories: Conveyor, material distributor, etc.

In total,there are two design for charcoal making line:

One:If your raw material is biomass wood sawdust, there are several steps to make briquettes:

1. The frist step is crush biomass wood sawdust become small size, less than 3mm.

2. The second step is dry raw biomass wood sawdust, in order to reduce the moisture less than 12%.

3. The third step is use press machine produce briquette.

4. The fourth step is carbonize briquette become charcoal.

Two: If your raw material is Toner, there are several steps to make briquettes:

1. Shredder machine:If your raw material is wood log, coconut shell they need cut into small pieces before drying.

2. Rotary dryer/Air flow dryer: if you raw material moisture higher 30%, before carbonizing it need to dry.

3. Continuous carbonization furnace: carbonizng the raw material into charcoal.

4. Charcoal crusher:crusher the charcoal into less than 5mm powder.(Choose configuration)

5. Charcoal and binder mixer: mixing charcoal powder and binder(we supply you formula).

6. Charcoal briquette machine:we supply all kinds of charcoal briquette machine.accordingto your require.

7. Charcoal briquette dryer:Drying the charcoal briquette and then can packing it directly.(Choose configuration)

Save Time! Get A Detailed Quotation Quickly.