Charcoal making machine, also known as charcoal production line, consists of several machines. First, the raw materials are pulverized into sawdust with a diameter of less than 5mm using a wood crusher. Then, the sawdust is dried using a rotary type of sawdust dryer to reduce moisture. Next, the material is shaped using a briquette machine. Finally, it is pl...

Charcoal making machine, also known as charcoal production line, consists of several machines. First, the raw materials are pulverized into sawdust with a diameter of less than 5mm using a wood crusher. Then, the sawdust is dried using a rotary type of sawdust dryer to reduce moisture. Next, the material is shaped using a briquette machine. Finally, it is placed in a carbonization furnace for carbonization.

This series of biomass carbonizing machines can process wood branches, sawdust, rice husk, coconut shells, straw, bamboo, plan kernel shells, and other waste biomass materials into charcoal. And the charcoal products can be hookah or shisha charcoal, barbecue charcoal, honeycomb coal, and various types of charcoal briquettes.

Our factory makes and sells biomass charcoal machines. They can customize charcoal plants and offer processing solutions to customers at good prices, both in and outside the country.

Raw material:

To make lump charcoal or charcoal powder from biomas materials (wood, wood branch, leaves, coconut shell, coconut dust, bamboo, palm thread, palm kernel, sugarcane bagasse, rice husk, cotton stalk, jute stick, or other agricultural wastes)

The raw materials could be any waste from agriculture or forestry. Such as: wheat straw, sunflower husk, coffee husk, soybean husk, rice husk, wood chips, sawdust, tae waste, cotton stalk, paddy straw, peanut husk, and any other type of agro-forestry waste.

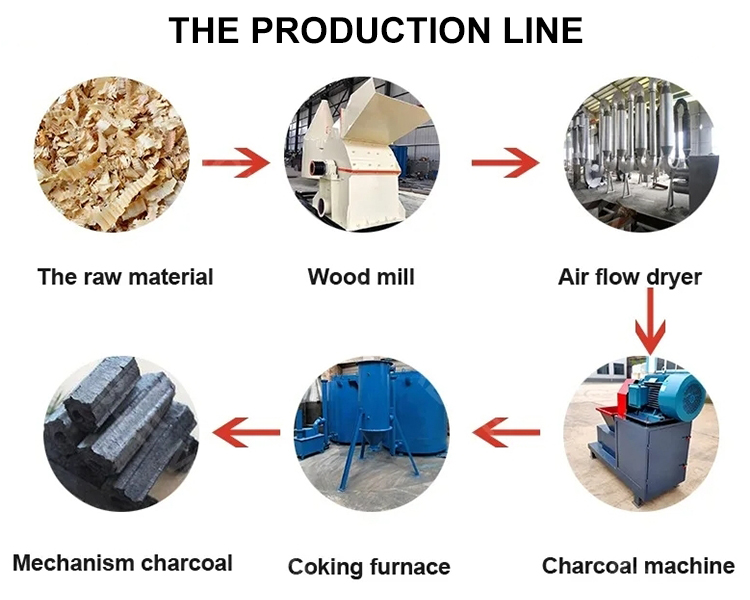

Charcoal production can be divided into four steps:

1. Crushing:

-Raw materials are put into a crusher and crushed into sawdust particles (approximately 5mm in fineness).

2. Drying:

-The crushed pellets are dried in a dryer, controlling the moisture level at 8-12%.

3. Rod making:

-The crushed and dried raw material is processed in a high temperature and pressure bar making machine, forming semi-finished bars.

4. Carbonization:

-The semi-finished charcoal bars are carbonized in a carbonization furnace and cooled down, resulting in finished charcoal.

The sawdust briquette charcoal line can be equipped with conveyor belt, automatic feeder and dispenser.We can configure the right production line for you according to the output you need.

Save Time! Get A Detailed Quotation Quickly.