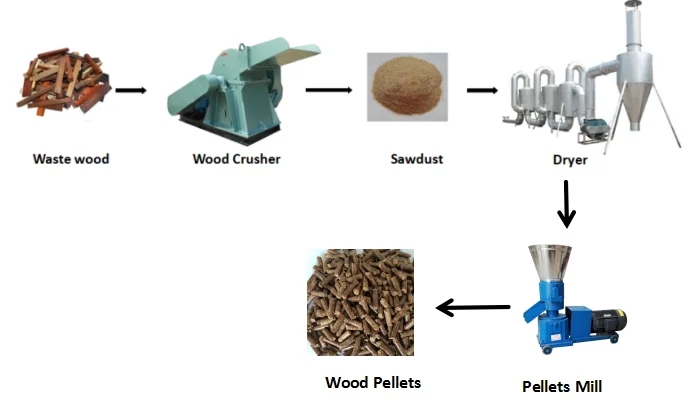

Flat die wood pellet machine is the use of crops corn stalk, straw, straw, peanut shell, corn cob, cotton stalk, soybean stalk,rice husk, weeds, branches, leaves, sawdust, bark and other solid waste as raw materials, after crushing, pressure, densification,molding, become a small stick solid rest pellet fuel. Pellet fuel is made of wood chips and straw scale...

Flat die wood pellet machine is the use of crops corn stalk, straw, straw, peanut shell, corn cob, cotton stalk, soybean stalk,rice husk, weeds, branches, leaves, sawdust, bark and other solid waste as raw materials, after crushing, pressure, densification,molding, become a small stick solid rest pellet fuel. Pellet fuel is made of wood chips and straw scales by pressing roller and ring die at room temperature. The density of raw materials is generally about 110-130kg/m3, and the particle density after molding is greater than 1100kg/m3. It is very convenient for transportation and storage, and its combustion performance is greatly improved.

Flat die sawdust pellet machine is mainly used for crude fiber compression molding, such as corn stalk scale, wood chips of various crops such as rice husk, cotton stalk, weed stalks scales, living garbage, factory waste, bonding rate is low, it is difficult to molding material granulating, rural farming farmer and farm feed particles, also can be applied to bio-bacterial

manure, organic fertilizer and compound fertilizer granulation in low temperature. The motor drives the machine spindle to rotate after changing speed through the reducer, the spindle is connected with the press roller shaft, the mold is static, the press roller and the mold material friction rotates, the material is pressed out through the mold, the cutter cuts off the pressed material and then falls into the dumping plate, thrown to the machine hopper, the pelleting is completed.

Parameters:

We also offer different diameters of pellet machine grinding mould. (The length of pellets can be adjusted freely)

| Model | Capacity | Power | Reducer | Rollers Number | Weight | |

| Flat Die | KL-200 | 100-200kg/h | 11kw | / | 2 | 520kg |

| KL-300 | 200-300kg/h | 18.5kw | KAF 87 | 2 | 700kg | |

| KL-400 | 300-500kg/h | 30kw | KAF 107 | 2 | 920kg | |

| KL-500 | 500-600kg/h | 55kw | KAF127 | 2 | 1400kg | |

| Ring Membrane | KL-560 | 1-1.5t/h | 90kw | YFJ 560-280 | 2 | 5t |

| KL-650 | 2-2.5t/h | 132kw | YFJ 560-315 | 2 | 6.2t | |

| KL-750 | 2.8-3.2t/h | 160kw | YFJ 700C-315 | 2 | 7.5t | |

| KL-850 | 3.5-4t/h | 220kw | YFJ 860C-355 | 2 | 9.5t | |

This machine can be installed with motor or diesel engine, which can be selected according to your actual needs.High-power machines can be equipped with diesel generators.

Finished Product:

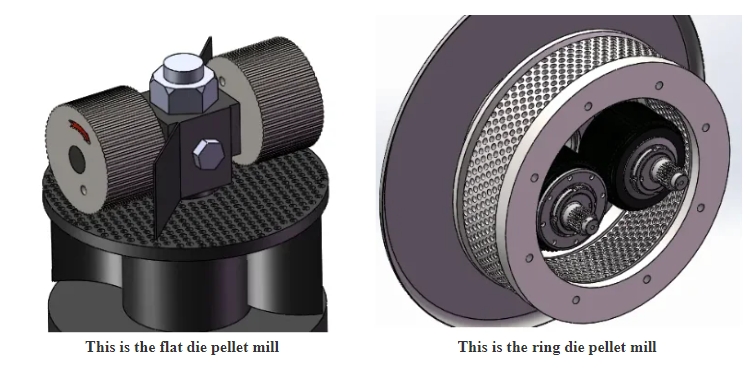

The Difference Between Flat Die Pellet Mill and Ring Die Pellet Mill

1. Feeding Method: Ring Die Pellet Mill adopt mechanical forced feeding, to enter the pelletizing room by high-speed rotation and centrifugal distribution. The material is distributed by scraper, which is non-uniform feeding. The Flad Die Pellet Mill is to feed material vertically by the weight of material itself. The material come into the pelletizing room is equally feeding.

2. Pressure: In the moulds with the same diameter, the diameter size of ring die have the diameter limit of ring die mould, so the pressure is limitated. The diameter size of flat die have not limitation by the moulds, which can increase the inner bearing room. Selection of larger roller bearings can enhance the bearing capacity, not only increasing the suppress power of press roller, but also to extend the service life of machine.

3. Discharge Methods: The Ring Die Pellet Mill belongs to hihg rotation speed, at a high rate of damaged materials when discharge. The flat die is low rotation speed with low breakage rate.

4. The Conditioning Ways of Press Roller: Ring Die Pellet Mill use the two screw at the eccentric wheel in the middle of press rollers. The Flat Die Pellet Mill is to use screw thread column m100 center adjust devcies, which can prop up hundreds tons, fall stable, soft touch, equal in pressure. It can be adjusted in two ways, manual and hydraulic self-regulation.

Product Line:

Save Time! Get A Detailed Quotation Quickly.